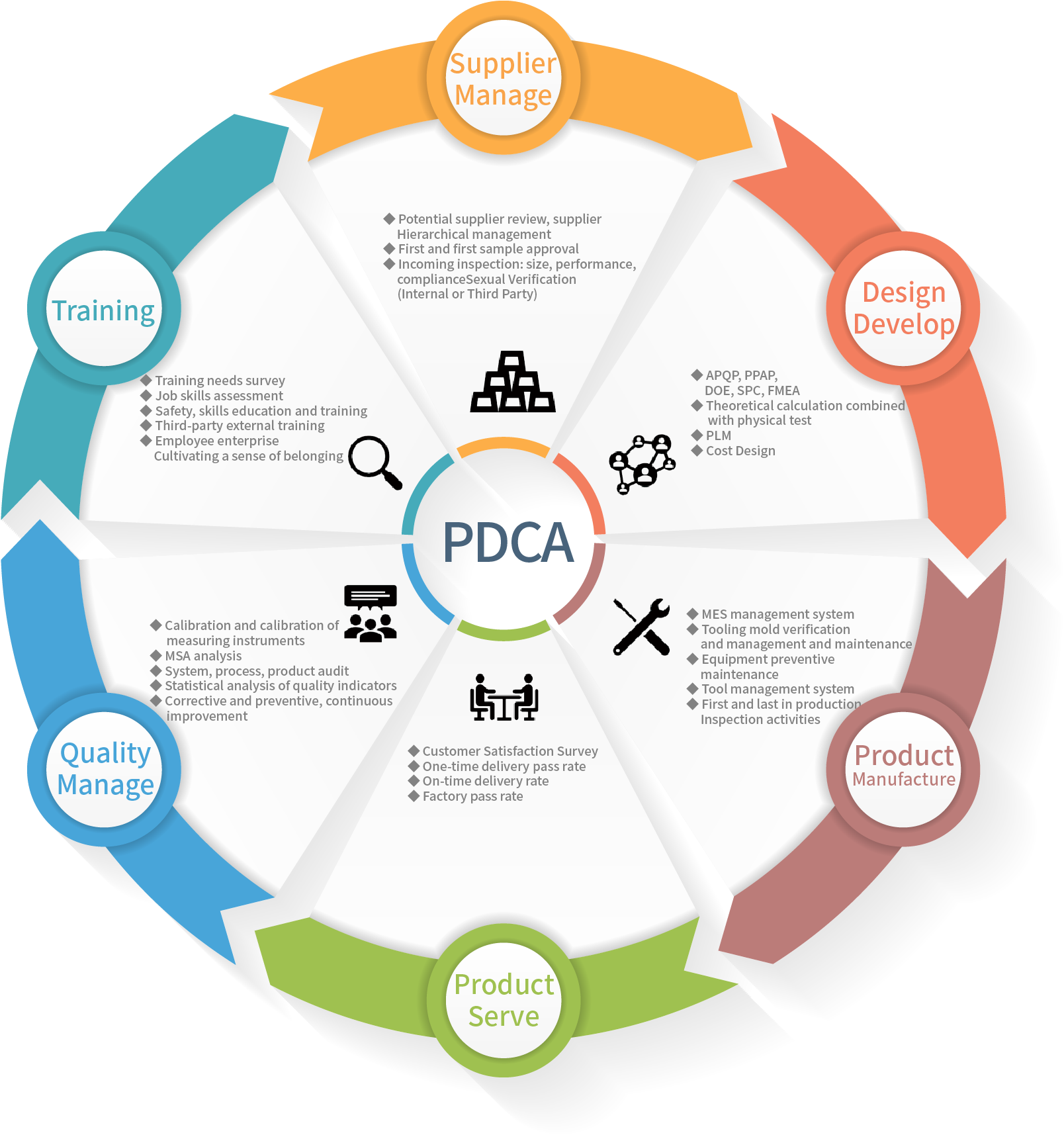

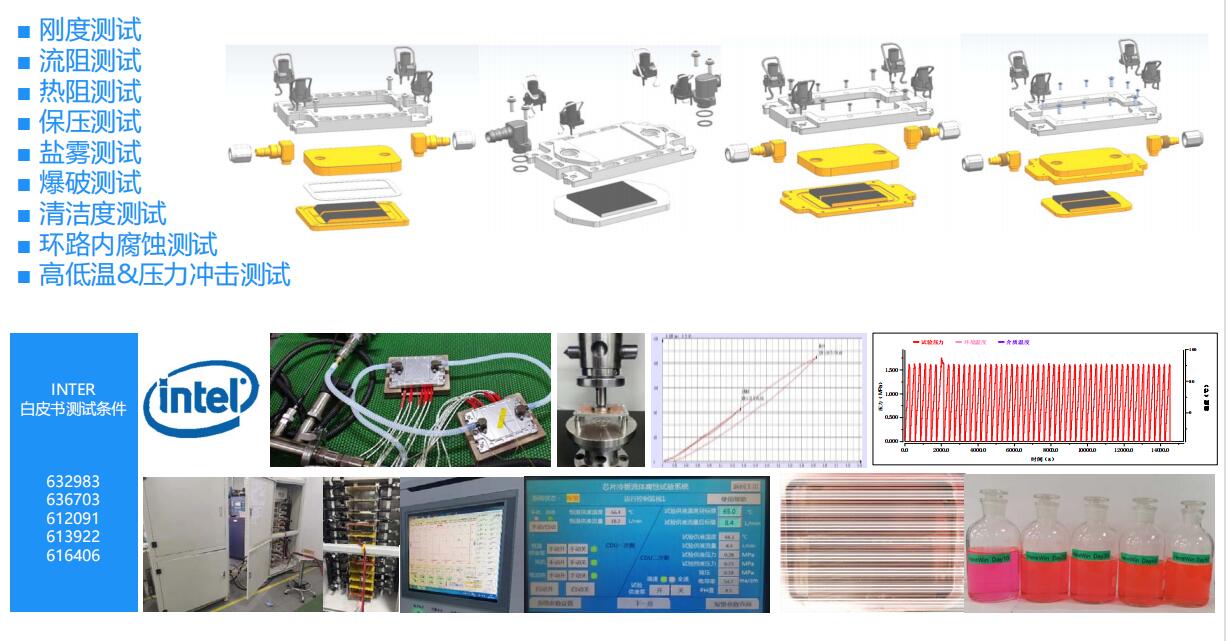

Cold Plate Test

■ Stiffness test

■ Flow resistance test

■ Thermal resistance test

■ Holding pressure test

■ Salt spray test

■ Burst test

■ Cleanliness test

■ In-loop corrosion test

■ High and low temperature & pressure shock test

Water cooling plate structure

Buried copper tube structure, vacuum brazing, FSW welding, electron beam welding, diffusion welding

Buried copper pipe | Simple form and structure, low cost, low heat dissipation power |

Vacuum Brazing | High heat dissipation power can be formed inside by machining, stamping fin filling, etc. The disadvantage is that the material is in an annealed state after welding, and heat treatment is required to increase the strength of the material and it is easy to deform |

FSW welding | High welding reliability, low risk of leakage, and the disadvantage of surface-to-surface contact welding cannot be implemented |

Electron beam, diffusion welding | The cost is high, and it is basically used for parts with special requirements such as military products |

Pipe connection form

Soft connection adopts PTFE corrugated pipe, PTFE steel wire winding pipe, EPDM rubber hose, hard connection adopts oxygen-free copper pipe, stainless steel pipe connection

Connection form of pipeline and cold plate

Use tapered fittings, O-ring radial, face seal or connector form connections

Trap

The processing form of stainless steel tube argon arc welding or stainless steel laser welding

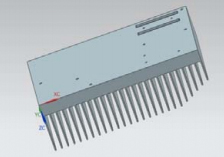

Traditional Air-cooled Radiator

The use of aluminum extrusion, shovel teeth, and tooth shaping to increase the area of the heat dissipation fins and improve the heat dissipation power

Aluminum extrusion | 6061, 6063 and other materials, the fin height is not more than 20 times the fin spacing, and the fin thickness is more than 1.5. |

Shovel tooth type | 1060 or 6063F material, the theoretical fin height is unlimited, the material is soft, usually the fixing hole needs to be used with the wire screw sleeve. |

Shaper | Since the fins and the base plate are combined, the thermal resistance is increased. |

Heat Pipe Radiator

On the traditional air-cooled radiator substrate, a sintered heat pipe is added to improve the temperature uniformity of the substrate and improve the heat dissipation power. The heat pipe is installed by pressing, gluing, and soldering.

Blown Plate Phase Change Heat Sink

The use of inflatable plates as fins has the advantages of high heat dissipation power, and the disadvantage is that the installation direction is determined by gravity.

Substrate Phase Change Heat Dissipation

Suitable for high-power heat dissipation requirements, the disadvantage is that the installation direction is determined by gravity.